XT Acrylic Sheet

TPPLGLAS XT Acrylic Sheet, Manufactured by Tilara Polyplast Pvt Ltd. is a thermoplastic sheet that is an alternative of Polycarbonate when extreme strength is not compulsory. It is often preferred because of its moderate properties, easy handling, fabrication and other processing. TPPLGLASS XT Acrylic Sheet has better scratch resistance properties than other conventional sheet.

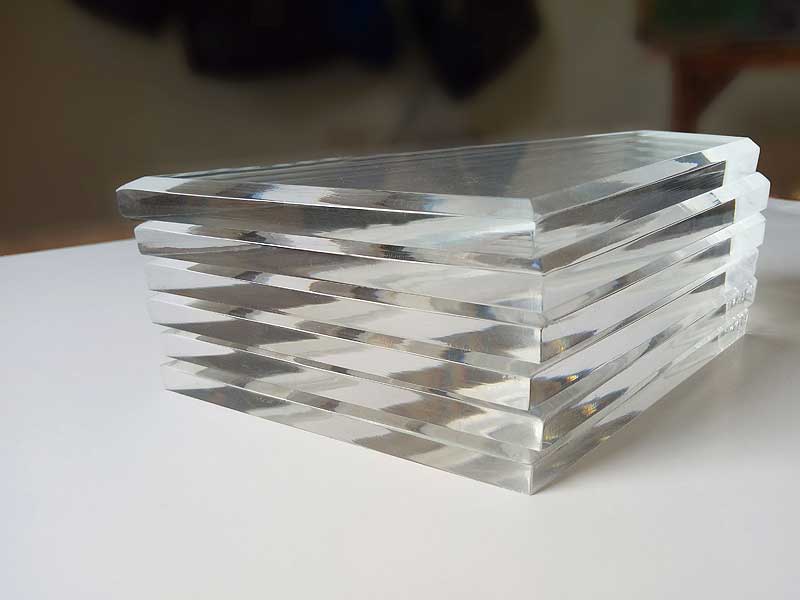

TPPLGLAS XT Acrylic Sheet manufactured by modified grade MMA resin which has higher scratch resistance with best impact resistance, weather resistance and thermal resistance. As per it's better weather and UV resistance, it’s also perfect for outdoor application. It has transmittance up to 92% of visible light and give best reflection from each of its surface. Our moderate extrusion technology process maintains product quality like transparency, color, accurate thickness and other object.

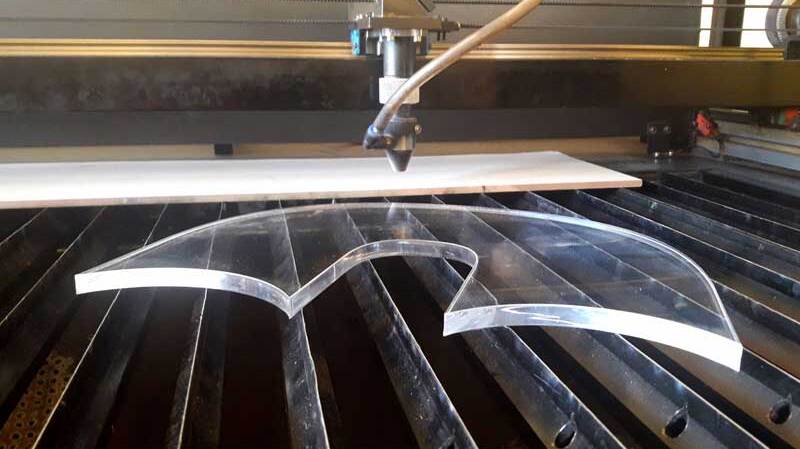

TPPLGLAS XT Acrylic Sheet is odorless that can be easily thermoform, blow, bend, print and laser without any excruciation.

APPLICATIONS

Exhibition Booths

Interior and Exterior Lighting

Cosmetics

Museum Casings

Noise-reducing Walls

Signage and Advertising

Aquarium

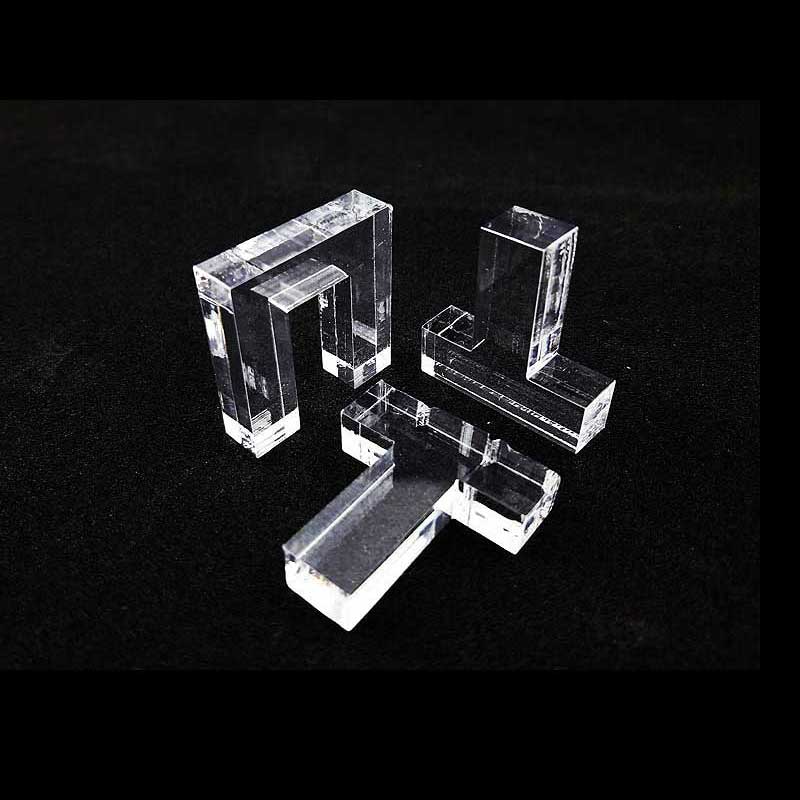

Gift Articles and Trophy

KEY FEATURES

Excellent thickness tolerance

Optical Clarity

Light weight

High gloss surface on both sides

Hard wearing

Weather resistant

Easy to bend and shape

Economical

Suitable for vacuum forming

POLYCARBONATE SOLID SHEET

| GENERAL | ||||

|---|---|---|---|---|

| General Properties | Conditions | Test Method | Unit | Value |

| Density | ISO 1183 | g/cm3 | 1,19 | |

| Water Absorption (24h) | 23 °C / 50% RH (24h) | ISO 62 | % | 0,3 |

| Moulding Shrinkage | ASTM D-955 | % | 0,2-0,6 | |

| MECHANICAL | ||||

| General Properties | Conditions | Test Method | Unit | Value |

| Tensile Strength at Break | 23 °C | ISO 527-2 | MPa | 83 |

| Elongation at Break | 23 °C | ISO 527-2 | % | 7 |

| Tensile Modulus | 23 °C | ISO 527-2 | MPa | 3200 |

| Flexural Strength at Break | 23 °C | ISO 178 | MPa | 120 |

| Flexural Modulus | 23 °C | ISO 178 | MPa | 330 |

| Charpy Impact Strength with Notched | 23 °C | ISO 178-1ea | kj/m2 | 2 |

| Izod Impact notched | ISO 178 | kj/m22,1 | ||

| Rockwell Hardness M Scale | ISO 2039-2 | M-scale92 | ||

| THERMAL | ||||

| General Properties | Conditions | Test Method | Unit | Value |

| Vicat Temperature | 50 N | ISO 306 | °C | 105 |

| Deflection temperature under load | 1,8 MPa | ISO 75 | °C | 100 |

| Coefficient of linear expansion | ISO 11359-2 | mm/m°C | 0,07 | |

| THERMAL | ||||

| General Properties | Conditions | Test Method | Unit | Value |

| Dielectric Strength | DIN53481 | kV/mm | 20 | |

| Dielectric Constant | 1 KHz | DIN53843 | 3,1 | |